‘Print it, O.T.!’

Students Use 3D Technology to Design Life-Changing Tools

The simple act of sipping water through a plastic straw was a challenge for Stephanie Jacob’s patient, a 46-year-old mother who suffers from Amyotrophic Lateral Sclerosis (ALS), a neurodegenerative disorder also known as Lou Gehrig’s Disease.

“She experienced extreme weakness in her hands and found it difficult to grasp objects,” said Jacob, a third-year occupational therapy (OT) student at Touro College School of Health Sciences. During treatment, the client would need Stephanie to hold the straw for her at the perfect height and position in order to drink without assistance.

The solution to this problem would appear to be a ‘straw stabilizer.’ “The straw stabilizer may seem like a simple and small product, but it can truly be life-changing to patients with these kinds of disabilities,” said Jacob.

The straw supports already on the market–consisting of a metal brace with several holes−were clumsy, expensive and not readily available.

Custom-Made Treatment

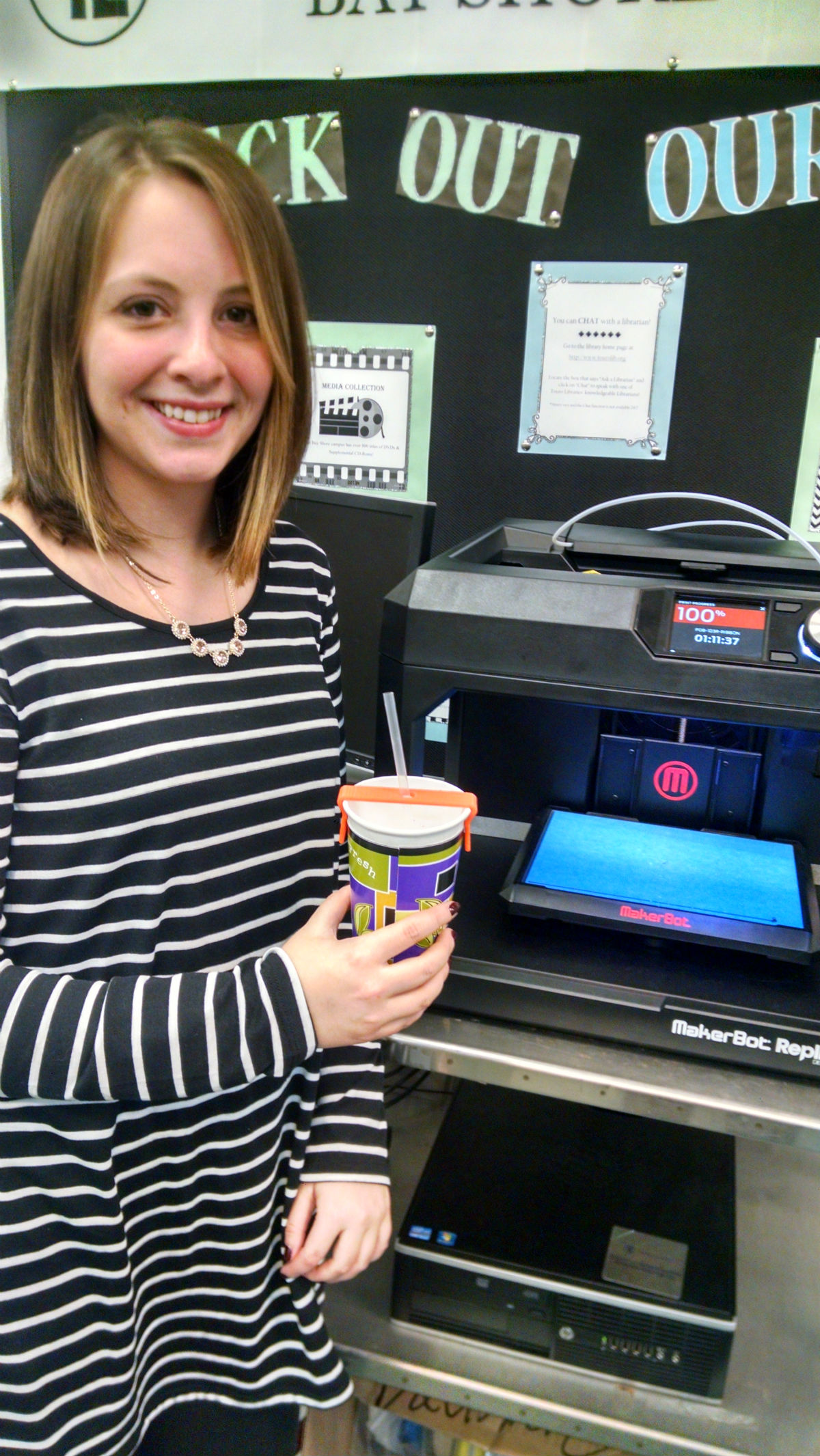

Enter the Makerbot Replicator, the new 3D-printer residing at the SHS library in Bay Shore. Introduced for the mass market just a few years ago, 3D printers are used to make all kinds of prototypes and products−from eyeglass frames and toys, to airplane parts and prosthetic hands. The “printing” is accomplished when an extruder (think Play-Doh Fun Factory) builds layer upon layer of plastic filament in specific shapes and sizes until an object is created.

After submitting her case study, Jacob made a rough model from moldable splinting material. With guidance from OT Professor Blanche Leeman and librarian Laurel Scheinfeld, who heads the project, the design was converted into a programmable file by a bioengineering team at the University of Cincinnati, before being uploaded into the Makerbot. The result? A custom-made straw support that is more stable, adaptable and user-friendly.

What’s exciting about the 3D-printer to health care professionals is its ability to custom design or modify−on site−assistive devices for people with disabilities whose needs are not being met with existing equipment. As Jacob points out, “What good is a ‘sock aid’ that cannot adapt to anyone with a wide foot?”

“3D printing is filling a large void in rehabilitative healthcare,” said Prof. Leeman, who is Stephanie’s faculty advisor. “For pennies, Stephanie was able to bring to fruition her goal of facilitating a meaningful activity for her client.”

As training on the Makerbot continues, Professor Leeman extols the educational value for students working with state-of-the-art 3D-printer technology, as well as future collaboration with engineering students like those from the University of Cincinnati.

“Touro’s occupational therapy students are on the cusp of bringing 3D-printing knowledge with them into the workforce after graduation, as well as adding marketable skills to their resumes,” said Professor Leeman.

Throughout the process, Stephanie Jacob remains focused on the goals of the OT program. “Occupational therapy is all about getting our clients to be as functional as possible in their daily lives,” said Jacob. “3D-printing is another way we can further customize our treatments.”

The project was funded in whole or in part with Federal funds from the Department of Health and Human Services, National Institutes of Health, National Library of Medicine, under Contract No. HHSN-276-2011-00003-C, with the University of Pittsburgh.